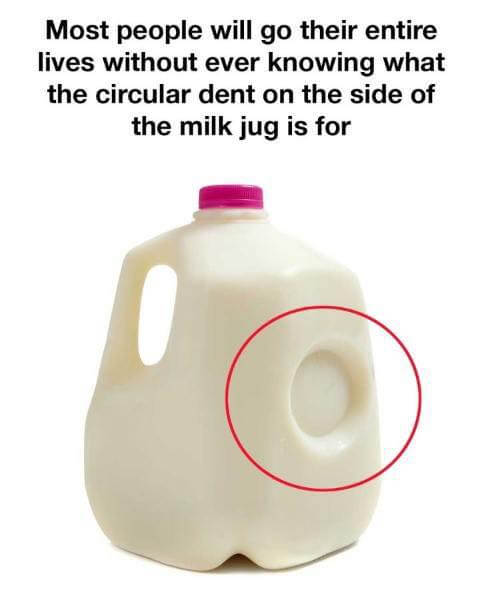

Most of us barely notice the small, round dent on the side of a plastic milk jug. At first glance, it seems like a random design choice—or maybe even a manufacturing mistake. But that subtle indentation is actually a clever piece of engineering with multiple purposes.

A Built-In Pressure Valve

Milk jugs are usually made from high-density polyethylene (HDPE), a lightweight and cost-effective plastic. Because the walls are thin to save material, the jug is susceptible to pressure changes. That small dent flexes as the milk expands or contracts, helping prevent cracks or ruptures if the jug is bumped, dropped, or exposed to temperature shifts. Think of it like an expansion joint in a bridge, silently keeping the structure intact. That faint pop you hear when you set the jug down? That’s the dent doing its job.

A Built-In Shock Absorber

Life can be rough on milk jugs—they get jostled in grocery bags, tipped on countertops, or even dropped on the floor. Without the dent acting like a mini crumple zone, the plastic could easily crack or leak. It softens impacts, protecting both the jug and your kitchen surfaces.

A Sustainability Champion

The dent allows manufacturers to use thinner walls without sacrificing durability. Less plastic means lower production emissions, and lighter jugs require less fuel for transportation. This tiny design tweak significantly reduces environmental impact.

Helping Recycling Too

Even after the milk is gone, the dent plays another role. It makes crushing the jug easier, reducing its volume and simplifying the recycling process. Some brands even incorporate logos or measuring guides into the dented area, merging functionality with style.

Next time you grab a milk jug from the fridge, take a moment to appreciate that little dent. It’s not a flaw—it’s quiet ingenuity, proving that even the simplest everyday objects are shaped by thoughtful design and practical engineering.